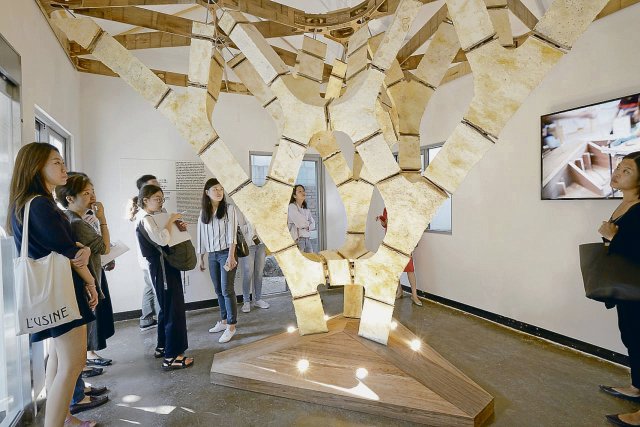

The “Mycotree”, a structure of mushroom myzel and bamboo, was seen in 2017 at the Biennale of Architecture and Urbanism in Seoul.

Foto: Silk and Salt Images

In mushrooms, many think primarily of the food and then their importance for the ecosystem of the forest. But now there is great interest in the potential of fungi as a renewable raw material for environmentally friendly composite materials. The spectrum of the possible uses ranges from food packaging to furniture to building materials.

Sustainable building materials from mushrooms could shape the construction of the future, because these are light, resistant, water -repellent and compostable. In combination with proven regenerative raw materials such as wood, clay or straw, mushrooms – also because of their excellent ecological footprint – offer a basis for very different composite materials.

But not all mushrooms are suitable. So far we have known six million species, of which only 120,000 have been researched. In the projects for new building materials, you only work with white rot. The black molds, on the other hand, are harmful to health and are out of the question as materials. The white rot mushrooms include all mushrooms.

To produce building material based on mushroom, you do not use the above -ground fruiting body, which only makes up the smallest part of the organism. Rather, international research focuses on mycelium, i.e. the underground network of cell threads (hyphae). Depending on the type of mushroom, this network can reach a size of over a square kilometer depending on the mushroom type.

Growing building blocks

The production of composites, such as cuboids that are used like wall stones, is quite simple and would also be implemented in empty industrial halls or mining tunnels. For the manufacturing process, agricultural residues such as grain Prussia or wood chips are mixed with water and the mycelium. The residues form the substrate, i.e. the food for the mushrooms. In the course of the metabolism process, it runs through a fine network of Myzel. In this way, a purely organic composite material is created in the growth phase of about two to three weeks in the incubator, which can be brought into a variety of desired forms and stabilized by thermal treatment. In the end, for example, it can take the shape of a leather -like fabric or be a composite material.

In this way, fungal materials can be breeded with very different properties. Durable, stretchy, tear -resistant, tight, elastic, open -pored or soft and fluffy – almost endless possibilities are open. What the “bred” result looks like depends on the one hand on the combination of mushroom type and substrate. On the other hand, parameters such as temperature, air humidity and the duration of the mushroom growth determine which properties the end product has. The growth is stopped at the end by heating the mushroom myzel.

Nd.Diewoche – Our weekly newsletter

With our weekly newsletter . We’re Doing Look at the most important topics of the week and read them Highlights our Saturday edition on Friday. Get the free subscription here.

As a result, you can produce flexible layers, but also solid, thick blocks, so that the material can be used in different areas. The composites are suitable for both the new building and the renovation: they are heat -insulating, soundproofing, moisture -regulating and fire -resistant. In addition, they can be used as a substrate for a new structure or simply composted at the end of their use.

Research for serial production

In the meantime, several universities and institutes in Germany have dealt with research on mycelical building materials and are making progress in the direction of serial production. Basic research on the subject is in particular Vera Meyer from the TU Berlin and Dirk Hebel from the Karlsruhe Institute of Technology (KIT). They are considered the leading experts for building with mushroom myzel.

Already in 2017, the KIT team around Dirk Nebel, together with the Block Research Group of the ETH Zurich, presented a supporting construction made of fungal material at the Biennale of Architecture and Urbanism in Seoul. The “Myco Tree” illustrated how well biodegradable materials and lightweight technique complement each other. At the moment, the production of wood-based material panels, for example OSB panels. Conventional plates contain up to 15 percent glue and are therefore to be treated as special waste when disposal. Alternatives are now to be found for the chemical glue.

With a 40-person team at the TU Berlin TU, Vera Meyer is based primarily on stand mushrooms-which includes around 30 percent of all mushroom types-in order to transfer some areas of the energy-intensive construction industry, such as the insulation materials, into a biotechnological circulation economy. Mushroom myzel instead of petroleum -based materials is to become a basic resource for composite materials in the areas of buildings and furniture. The first house is planned entirely from mushrooms for 2030.

A research team from the Fraunhofer Institute for Environmental, Security and Energy Technology (prospect) tests in his “myzel technique” how mushroom-based materials can be produced, shaped and functionalized, and tests their behavior. In addition, companies are given an introduction to the topic and advises them on the potential of the mycelical material. At the international building fair in January 2025 in Munich, caution presented, among other things, the prototype of a facade element. In itself, the element combines a combination of integrated photovoltaics for electricity extraction, weather protection and thermal insulation made of fungal material. It was developed in a joint project with the Fraunhofer Institute for Solar Energy Systems (ISE).

Good insulation properties

Also at the Fraunhofer Institute for Applied Polymer Research (IAP) in Potsdam, researchers deal intensively with mycelical materials from agricultural residues. Hannes Hinneburg and his team convert locally available plant -based waste products into sustainable materials, whereby focusing on mushrooms or tree mushrooms such as the oyster sides or the tinder sponge. In particular, the team is currently working on the development of mushroom -based insulation boards for interior design, since the material has similarly good insulation values as the foam -expanded polystyrene (EPS). In testing is also used as a sound absorber for wall and ceiling. Such soundproofing would not only be sustainable, but also to convert material and space-saving into thin layers.

Even if there are currently no load-bearing components made of fungal material, there are a few companies that already develop and market other myzel composite materials for the construction industry. Wall panels, insulation boards and glue for mineral material or floor slabs from the organic composite materials are currently available. In Switzerland, for example, the company Mycho Suisse is one of the pioneers. It has been researching the potential of mushrooms for over ten years and combines cellulose fibers with Myzel to replace petrochemical products with sustainable alternatives.

The first house is planned entirely from mushrooms for 2030.

In the United States, the Ecovative Design company combines the Myzel, among other things, with grain plans or plant stems. The material can be used for packaging and decorative items such as candle holders, but also as a building material. The manufacturer offers the “Mushroom Insulation” as an insulation material, acoustic tile and sandwich panel. For the latter, the mushroom network is arranged between two layers of wood, with which it naturally combines through its growth process.

It is only a matter of time before the first products in this country are produced in serial production. The research laboratories work to expand the possible uses in the construction sector to load -bearing components. In the near future, the mushroom material should lose its exotic status as well as clay, straw or insulation from seagras.

Raw material also for textiles

In the future, we will probably not only come across houses whose sound insulation and interior walls were made with mushroom myzel and the decoration of which partly comes from the renewable raw material.

The Dutch designer Aniela Hoitink designs sustainable fashion from mushrooms with her company Neffa. It wants to help to create fewer textile waste. According to the designer, the mushroom tissue called “Myco Tex” is the only 3-D production of seamless and tailor-made textiles made of mushroom myzel. Once they have had their day, they can be easily composted.

By the way, if you would like to experiment with mushrooms, you can do this via Grown Bio. The manufacturer -based manufacturer of mushroom -based packaging offers a “Grow it yourself kit”, with which you can try out the material yourself and create your own products such as pots, sculptures and lamps.

sbobet88 sbobet sbobet sbobet88