Through the successful collaboration between the IBS – Technical Office Linz and Teckentrup, a decisive step was taken into the “future of product development”. By using virtual fire tests in the construction of fire doors, development times are shortened and product designs are significantly improved.

In a joint project, the challenge was to optimize the glass retaining strips of the glazing in fire doors – an essential element that maintains the integrity of the door under extreme conditions. The goal was a slimmer design that could be manufactured both safely and efficiently.

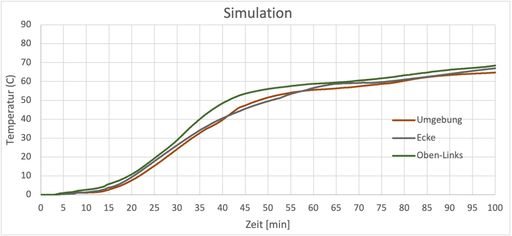

With the help of simulations, various design variants could be tested quickly and efficiently as virtual prototypes and physical effects in the building materials of the construction buildings could be recreated. Effects and impacts were understood by looking at the design, new possible solutions were developed, development risks were minimized and costs were saved.

The successful project by the IBS-Technisches Büro Linz and Teckentrup underlines the power of simulation in modern product development while optimizing resources and simplifying the production process.

The IBS Technical Office is a competent partner in the planning and implementation of fire protection measures in projects.

The service portfolio of the IBS – Technical Office includes the creation of fire protection concepts and reports, simulations of buildings, surface water as well as component development, escape route analyses, quality assurance of structural fire protection, and much more

OTS ORIGINAL TEXT PRESS RELEASE UNDER THE EXCLUSIVE RESPONSIBILITY OF THE SENDER FOR CONTENT – WWW.OTS.AT | BVO